Single-vendor solution shortens deployment from weeks to days with pre-configured chambers and cyclers.

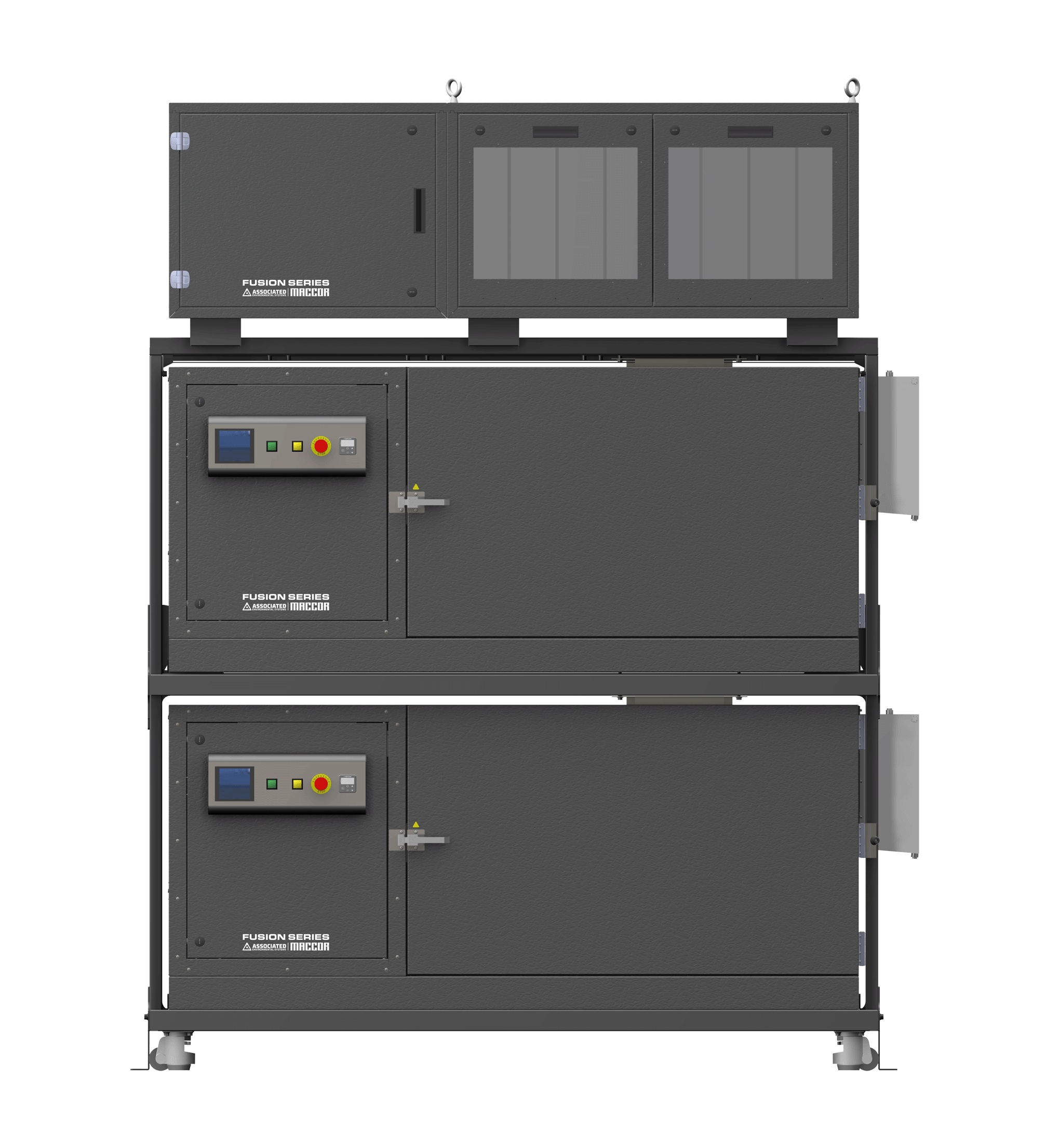

ACTON, MA / ACCESS Newswire / October 6, 2025 / Associated Environmental Systems (AES) and MACCOR Inc. today announced FUSION, a fully integrated battery test system. FUSION combines environmental chambers, battery test fixtures, and battery cyclers in a single pre-configured solution, eliminating integration delays and giving developers a faster, more reliable way to validate and improve battery performance. Manufactured in the U.S., FUSION reflects AES and Maccor's commitment to quality, customer confidence, and constant innovation.

Battery Testing Demands Outpace Integration Capabilities

Battery testing demand is accelerating across electric vehicles, consumer electronics, aerospace, military & defense, and energy storage. Laboratories and manufacturers are under pressure to validate more cells, modules, and packs in less time to keep pace with innovation.

Yet traditional test setups slow progress. Teams often juggle multiple vendors, separate purchase orders, and weeks of on-site integration to have chambers and cyclers communicate. Compatibility troubleshooting and custom programming can stretch deployments from days into months, delaying critical product development timelines. FUSION solves these challenges by providing everything in one fully compatible module that is ready for immediate use.

FUSION: A Complete Integrated Battery Testing Solution

FUSION is more than a chamber and a cycler in the same crate. It's a fully engineered system where hardware, wiring, safety, and controls are designed, validated, and tested to operate as one. This pre-engineered approach gives customers confidence that their system will work seamlessly before it arrives on site.

Each FUSION unit includes:

Maccor battery cyclers

AES environmental chambers

Integrated safety systems within the chamber

Pre-wired cables and wiring

Battery fixtures matched to cell formats

Unified control software - AESONE CONNECT® and Maccor Software Suite

"Customers can issue a single purchase order and receive a complete, turnkey product," said Mike Sandoval, Vice President of Business Development at Maccor. "This approach simplifies procurement, accelerates setup, and reduces risk. It gives customers a faster path to reliable test results."

With integration already solved, customers can accelerate testing programs at scale, redirecting resources toward innovation instead of troubleshooting. From coin cells to EV pack validation, FUSION helps teams focus on results rather than system setup.

"Customers consistently tell us their biggest frustration is making different systems communicate," added Aaron Robinson, Vice President of Sales and Service at AES. "With FUSION, the controls are already integrated and work together immediately."

Technical Capabilities of FUSION Battery Cell Tester Systems

FUSION is available in four configurations to meet a range of testing needs:

FUSION-24-016-3200: 200-400A per channel, scalable to 16 channels

FUSION-12-008-1600: 200-400A per channel, scalable to 8 channels

FUSION-08-192-0192: 192 channels at 1A max current each

FUSION-08-064-0960: 64 channels at 15A max current each

The FUSION series has a temperature range from -20°C to +80 °C and delivers ±0.5 °C stability and up to 90% return-to-grid efficiency for regenerative testing on the higher amperage solutions.

A Proven Partnership Powers FUSION

Such sophisticated integration requires extensive experience in both environmental chamber design and battery cycler engineering. AES has manufactured environmental chambers since 1959, deploying more than 200,000 testing channels. Maccor, the world's largest battery test system manufacturer, serves over 1,500 customers in over 50 countries.

Built on a decade of collaborative installations, AES and Maccor's combined expertise is now at the core of every FUSION system.

"FUSION is the culmination of years working directly with customers," said Robinson. "We are both US manufacturing companies, with a focus on technology. Our colleagues at both companies meld together as if we are the same company working toward the same goals. The best integrated technological solution with integrated support is something that is currently not offered in the field."

For More Information

FUSION details: https://www.associatedenvironmentalsystems.com/fusion-battery-test-system

https://www.maccor.com/fusion.html

Visit: associatedenvironmentalsystems.com and Maccor.com

About AES

Associated Environmental Systems (AES) manufactures environmental test chambers and integrated battery testing equipment from its Acton, Massachusetts, facility. Founded in 1959, AES is a trusted U.S. manufacturer supporting research and production teams with precise, reliable systems used worldwide.

CONTACT:

8 Post Office Sq Road, Acton, MA, 01720 USA

Sales@associatedenvironmentalsystems.com

About Maccor

Maccor manufactures testing equipment for the battery and energy storage market, serving as a pioneer and global leader in commercial battery test systems. Thousands of Maccor systems operate worldwide across consumer, automotive, and energy storage applications.

CONTACT:

4322 South 49th W Ave Tulsa, OK 74107 USA

Sales@maccor.com

SOURCE: Associated Environmental Systems

View the original press release on ACCESS Newswire