-- Originally posted on: https://cn-cob.com/blog-detail/what-are-microinverters

A micro inverter typically refers to inverters used in solar power systems with a power rating of 2000 watts or less and with module-level MPPT capability, officially called a micro grid-tied solar inverter. The term "micro" distinguishes it from traditional centralized inverters. Traditional solar power systems work by wiring all solar panels together in series or parallel to combine the direct current (DC) generated under sunlight, then using one central inverter to convert this DC power to AC for the grid. In contrast, a microinverter converts power for each panel separately. The main benefits are having separate MPPT control for each panel, which boosts the system's overall efficiency, plus it avoids common problems with central inverters like high DC voltage, poor low-light performance, and the so-called "bucket effect" (where system performance is limited by the weakest panel).

1. What Are Micro Inverters?

The term "micro" highlights the smaller size and lower power of microinverters compared to traditional centralized inverters, a microinverter is a device that individually tracks the maximum power point (MPPT) of each photovoltaic (PV) module and converts direct current (DC) power into alternating current (AC) for grid integration. Compared to centralized, string, and distributed inverters, micro inverters are the most compact and lowest-powered, typically rated below 1 kW.

Benefits of Microinverters:

Micro inverters can independently optimize the power output of each module, improving system efficiency even when shading or performance differences occur. They also provide an exceptional level of safety for residential or commercial solar installations.

Micro inverters are primarily used in distributed residential and small-scale commercial rooftop PV systems.

2. How Do Micro Inverters Work?

The working principle of a microinverter involves the following steps:

DC Input: The direct current (DC) generated by PV panels is transmitted via cables to the microinverter.

Maximum Power Point Tracking (MPPT): A microinverter contains an MPPT mechanism that monitors the output voltage and current of the PV panel to ensure maximum power extraction.

Inversion: The microinverter dynamically adjusts output voltage and frequency while converting DC power into AC to match the standard grid requirements (e.g., 230V/50Hz in Europe, 120V/60Hz in the US).

Synchronization and Grid Connection: The microinverter ensures that the generated AC power is synchronized with the grid and automatically shuts down during grid instability or outages for safety purposes.

Microinverters perform MPPT for individual PV modules or groups, convert DC power to AC for grid connection, fine-tune and monitor output from each module, and use high-performance integrated electronics to ensure efficient energy transmission and utilization.

Source of Diagram: Prospectuses from CNCOB

3. Key Features of Microinverters

4. Comparing Microinverters with Other Types of Inverters

As a core component in photovoltaic systems, inverters convert variable DC voltages generated by PV modules into grid-frequency AC power, serving as an essential part of system balancing. Commonly available inverter types include centralized, string, distributed, and microinverters.

The categories, definitions and descriptions, use cases, advantages, and disadvantages of central inverters, string inverters, hybrid inverters, and micro-inverter systems.

ClassificationDefinitionApplication ScenariosAdvantagesDisadvantages

Centralized PV Inverter

Centralized technology connects multiple photovoltaic arrays to a DC bus, which is fed into a single large inverter. Mainly suitable for situations like utility-scale solar farms, with unit capacities typically above 10kW.

Applicable for large-scale photovoltaic (PV) systems, such as utility-scale solar farms and building rooftops with ample space.

1. Few inverters required – simpler design, lower cost.

2. High conversion efficiency due to large-scale MPPT.

3. High system reliability and low operational costs.

1. Higher DC-side voltage, strict requirements for matching PV strings.

2. Ineffectiveness in partial shading due to limited string-specific capability.

3. Maintenance costs increase if the inverter fails since the entire system may halt temporarily.

String PV Inverter

String inverters attach independently to one PV string. Each string has its MPPT (Maximum Power Point Tracking) unit, which improves system reliability and energy production at the string level.

Suitable for distributed PV systems, including residential and small commercial rooftop systems.

1. Effective against partial shading effects and improves energy efficiency.

2. Higher flexibility in system expansion and adaptability to various installations.

1. Higher initial investment compared to larger centralized inverters.

2. More components increase maintenance complexity.

3. EMI (Electromagnetic Interference) from neighboring devices may impact its operation.

Distributed PV Inverter

Combines centralized and string inverter advantages. Multiple units operate independently but coordinate among systems, ideal for hybrid installations or medium-scale projects.

Can be used for combination projects where decentralized systems are beneficial but central management still adds benefits.

1. Maintains a balance between centralized adaptability and decentralized efficiency.

2. Simple wire configuration and system scalability.

3. Easy fault isolation and load sharing at output.

1. Managing coordinated communication across units is complicated and technology-intensive.

2. Fault tolerance thresholds depend on efficient monitoring systems.

3. Installation involves higher capital/project costs upfront before return on investment.

Micro Inverter

Each PV module is connected to its small inverter, performing energy optimization directly at the module level, ensuring maximum output under varied environmental conditions.

General applications include smaller rooftops or locations with more complex shading patterns, mismatched module orientations, or modular installation needs.

1. Modular installation provides maximum energy output per module.

2. Eliminates shading mismatch effects, suitable for small-scale, complex installations.

3. Simplifies monitoring and fault diagnosis.

1. High cost per watt compared to other inverter types.

2. Difficulty in centralized performance monitoring for broader systems.

3. May not be cost-efficient for large installations where centralized systems provide economies of scale.

After more than a decade of advancements driven by technological improvements, rising module efficiency, and increasing safety awareness among users, microinverters have achieved significant progress. As global carbon neutrality initiatives accelerate, microinverters—an important innovation in green energy—are transforming energy usage patterns through superior safety features and power generation efficiency.

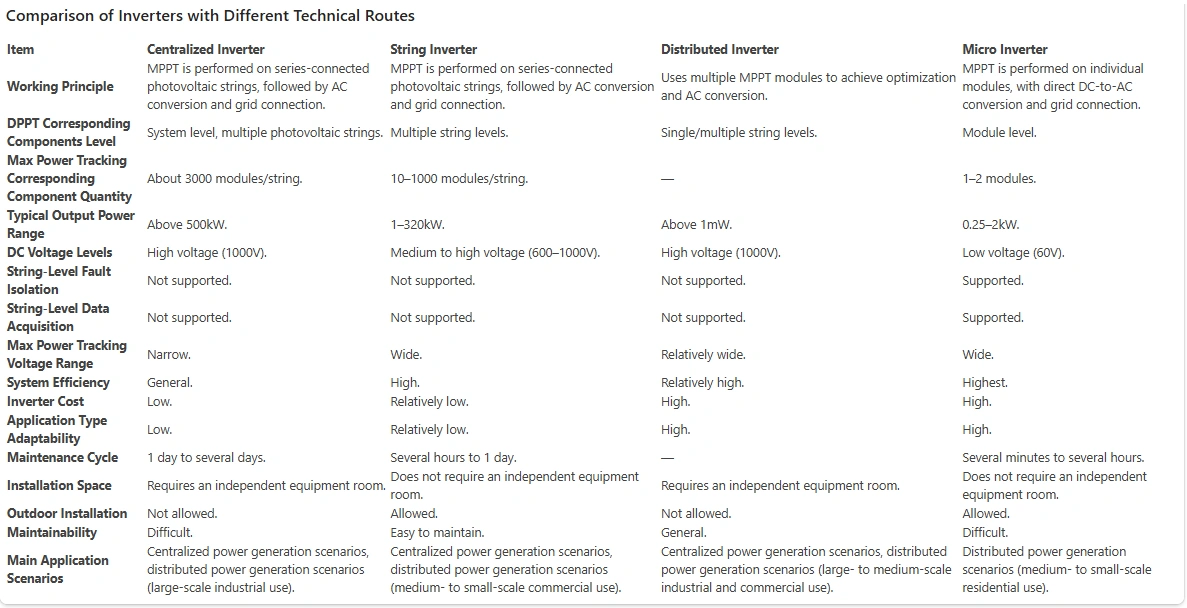

A Comparison of Different Technological Approaches of Inverters

# Comparison of Inverters with Different Technical Routes

5. Microinverter Market Landscape

North America and Europe are currently the largest markets for microinverters, with North America accounting for about 70% of shipments and Europe making up roughly 15-20%. Other regions such as Asia-Pacific hold relatively smaller shares. Globally, Enphase Energy leads the market while Chinese companies like CNCOB,Hoymiles Technology Co., Ltd., APsystems Inc., and DEYE are rapidly emerging as strong competitors.

In recent years, with the expansion of distributed PV systems, global shipments of microinverters have grown substantially—from 1.18 GW in 2018 to 2.28 GW in 2020—achieving an annual compound growth rate (CAGR) of 39.12%. Preliminary estimates indicate shipments surpassed 4 GW by 2023.

6. Key Domestic Enterprises Producing Microinverters

Hoymiles Technology Co., Ltd.: Established in Hangzhou in 2012, Hoymiles specializes in developing, manufacturing, and selling photovoltaic inverters along with other electrical conversion equipment widely used in distributed PV systems globally.

According to data from S&P Global Commodity Insights, Hoymiles ranked second globally in annual shipments of microinverters from 2021 through 2023.

Between 2019 and late 2023 alone, Hoymiles shipped over 3.12 million units across more than 180 countries/regions—a testament to its product quality recognized internationally.

Contact Info:

Name: CNCOB

Email: Send Email

Organization: CNCOB

Website: https://cn-cob.com/

Release ID: 89176133

If there are any errors, inconsistencies, or queries arising from the content contained within this press release that require attention or if you need assistance with a press release takedown, we kindly request that you inform us immediately by contacting error@releasecontact.com (it is important to note that this email is the authorized channel for such matters, sending multiple emails to multiple addresses does not necessarily help expedite your request). Our reliable team will be available to promptly respond within 8 hours, taking proactive measures to rectify any identified issues or providing guidance on the removal process. Ensuring accurate and dependable information is our top priority.