In the metal casting and foundry industry, the reliability of refractory components directly impacts production efficiency, safety, and product quality. Among these critical components, Bottom Pouring Bricks are indispensable, designed to withstand extreme temperatures, corrosive molten metals, and thermal shocks while ensuring smooth, controlled metal flow. From steel production to precision alloy casting, their versatile applications make them a cornerstone of modern foundry operations. Below is a detailed overview of their key uses and industrial value.

1. Core Application: Steel & Alloy Casting

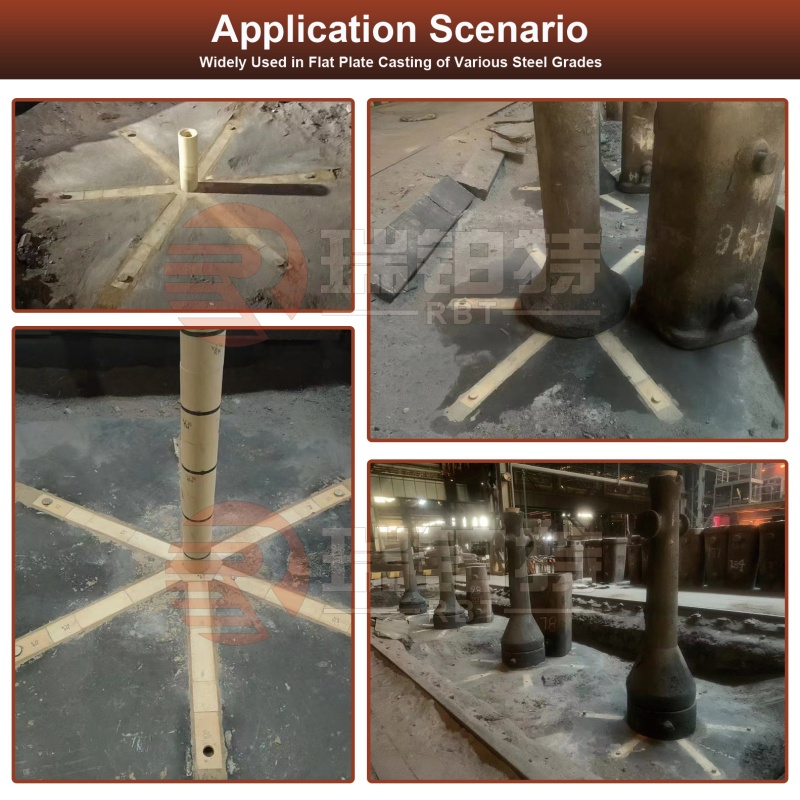

The primary use of Bottom Pouring Bricks is in steel and alloy casting processes. As key parts of ladle casting systems, they line ladles, form pouring nozzles, seat bricks, and sleeve bricks. Their precisely designed flow channels enable uniform, turbulence-free molten metal distribution, a crucial factor in reducing casting defects like porosity, inclusions, and surface irregularities.

In steel mills, these bricks play a vital role in bottom-pouring systems, maintaining the integrity of crucibles and channels during molten steel transfer. High-alumina and mullite-based variants offer exceptional resistance to molten steel and slag corrosion, extending ladle service life and minimizing maintenance downtime. For alloy casting—where precise chemical composition and temperature control are non-negotiable—Bottom Pouring Bricks ensure consistent pouring, preventing alloy segregation and enhancing final product quality.

2. Foundry Furnace Lining & Thermal Insulation

Beyond pouring systems, Bottom Pouring Bricks are widely used as lining materials for foundry furnaces, arc furnaces, and induction furnaces. With high thermal stability (withstanding temperatures over 1700°C), they effectively insulate furnace interiors, reducing heat loss and improving energy efficiency. This thermal insulation not only lowers operational costs but also creates a stable heating environment, essential for uniform metal melting and refining.

Their resistance to thermal shock prevents cracking and structural damage from rapid temperature fluctuations, ensuring longer furnace service life and reducing maintenance shutdowns. In converter steelmaking, for instance, these bricks support efficient bottom-blowing operations by maintaining gas flow stability and resisting erosion from high-velocity molten metal.

3. Precision Casting for High-End Industries

Precision casting sectors—including aerospace, automotive, and medical device manufacturing—rely heavily on Bottom Pouring Bricks for controlled, precise molten metal flow. In investment casting (lost-wax casting), they regulate flow rates into intricate molds, ensuring full filling without damaging delicate mold structures.

The uniform porosity of high-quality Bottom Pouring Bricks also aids in degassing molten metal, removing impurities and air bubbles that compromise the mechanical properties of precision components. For critical parts like automotive engine blocks or aerospace components requiring high strength and reliability, this precision makes these bricks an irreplaceable part of the production chain.

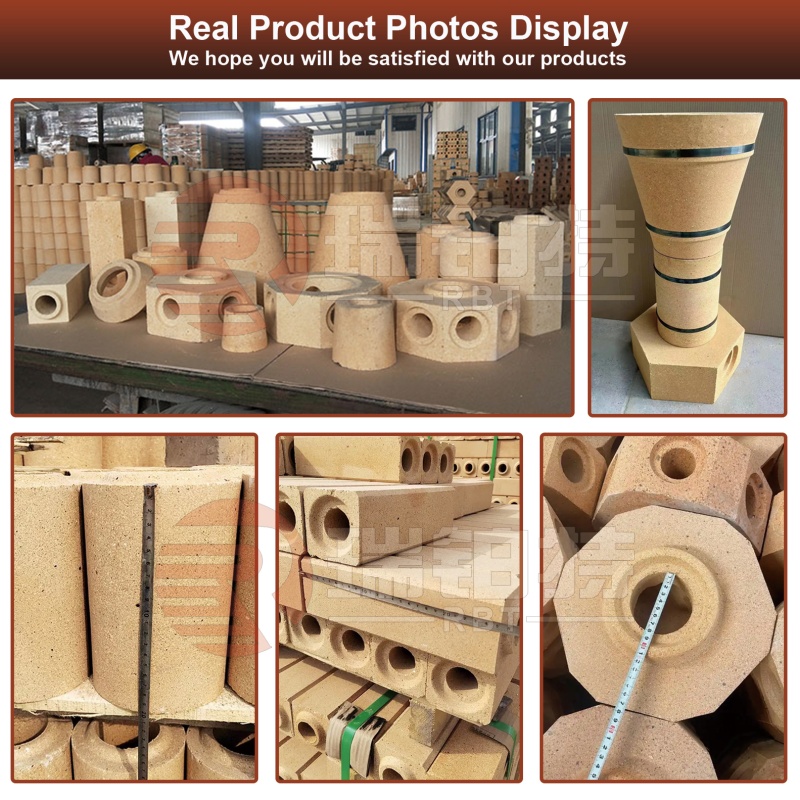

4. Customized Solutions for Diverse Needs

A key advantage of Bottom Pouring Bricks is their adaptability to diverse industrial requirements. Manufacturers offer customized options in terms of shape, size, and material composition to match specific processes: Clay-based bricks are cost-effective for medium-temperature non-ferrous casting (aluminum, copper); high-alumina bricks excel in high-temperature ferrous casting with superior corrosion resistance; mullite bricks are ideal for harsh, slag-prone environments like steelmaking ladles, thanks to their dense structure that prevents molten metal penetration.

Why Choose High-Quality Bottom Pouring Bricks?

Investing in premium Bottom Pouring Bricks translates to improved casting quality, reduced downtime, and lower long-term costs. Their durability and performance stability ensure consistent production output, while their versatility supports a wide range of foundry processes. Whether for large-scale steel production or precision component manufacturing, these bricks deliver the reliability and efficiency modern foundries demand.

For tailored Bottom Pouring Brick solutions that match your specific industrial needs, contact our team of refractory experts today. We provide high-performance products engineered to elevate your casting operations.

Media Contact

Company Name: Shandong Robert New Material Co., Ltd.

Email: Send Email

Phone: +86 15666531308

Address:10/F, Building A, Zibo New Material Trading Center, Zhangdian, Zibo

City: Shandong

Country: China

Website: https://www.sdrobert.com/