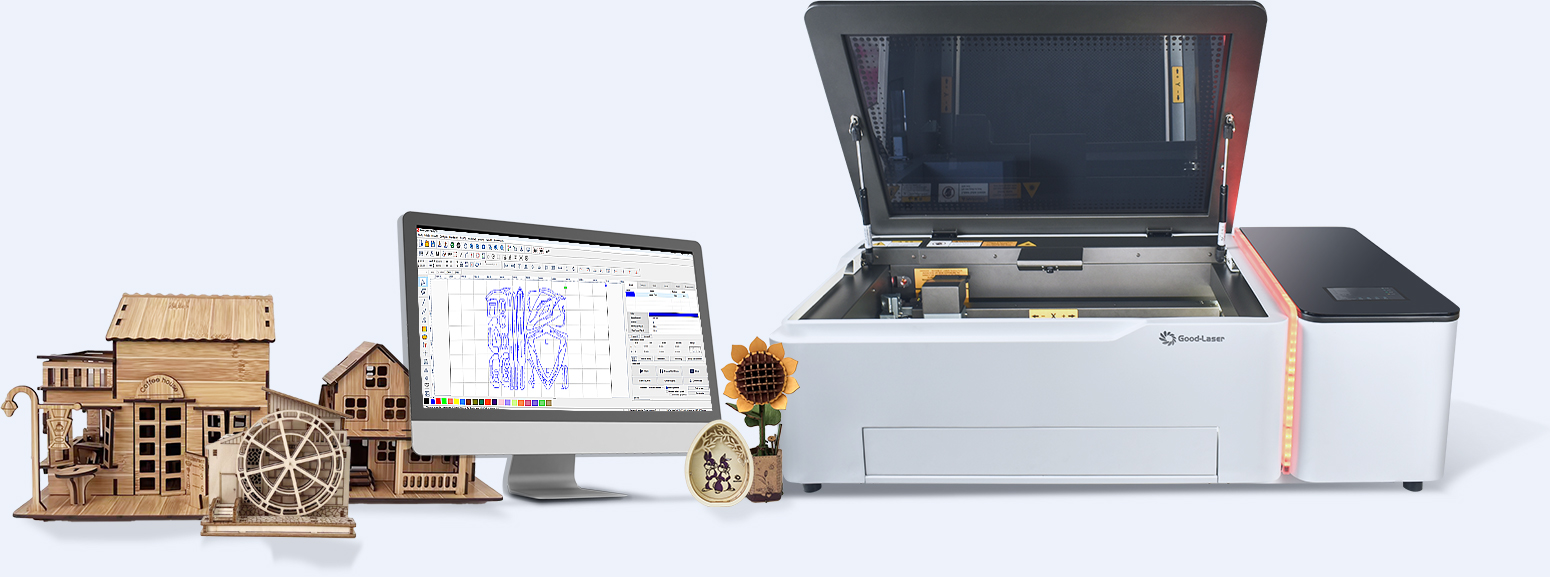

In the rapidly developing manufacturing and creative industries, laser technology is gradually becoming a core tool to improve productivity and creativity. As an industry-leading laser equipment manufacturer, Good-Laser has launched the Light 530 and Light 640 laser cutting and engraving machines with its advanced technology and innovative design, bringing new processing concepts to customers. Through more efficient and precise laser processing, the Light series not only meets the needs of industrial production, but also provides unlimited possibilities for personalized and customized creative designs.

Precision and innovation: the core strengths of the Light series

Good-Laser's Light series laser cutting and engraving machines inherit Good-Laser's consistent high precision and high stability. Its precise laser beam can perform non-contact processing on different materials, and the cutting and engraving effects are both at the industry-leading level. Whether it is fine non-metal processing, complex wood engraving, or difficult leather engraving, the Light series can provide processing effects beyond imagination.

Precision Control

The Light series laser cutting and engraving machines use advanced optical systems to ensure precise control of the laser beam throughout the entire processing process. Compared with traditional mechanical processing, laser cutting technology not only avoids contact wear, but also ensures accurate presentation of details. Whether it is a tiny pattern or a large-scale engraving, the Light series can achieve high-precision processing to ensure the quality of each product.

Efficient production

Another significant advantage of the Light series laser cutting and engraving machine is its excellent production efficiency. Traditional cutting and engraving methods usually require a lot of manual operation and have a slow production speed. Laser cutting and engraving technology can achieve full automation through computer programs, greatly shortening processing time and improving production efficiency. Whether it is single-piece customization or mass production, the Light series can efficiently complete processing tasks, greatly improving the efficiency of the production line.

Diversified applications: meeting the needs of different industries

The wide applicability of laser cutting and engraving technology is a highlight of the Light series. This series of equipment is not only suitable for processing traditional materials such as acrylic, wood, plastic, glass, etc., but also can perform fine engraving and cutting on a variety of soft materials such as leather, paper, cloth, etc. Therefore, the Light series is widely used in many industries:

- Home decoration: Provide customized services for the production of wooden furniture, wall decorations, and carved artworks to enhance product design.

- Fashion industry: Through precise engraving and cutting technology, it helps to achieve personalized design of clothing and leather products.

- Advertising industry: Achieve precise cutting and engraving of billboards, logos, and signs to meet personalized and creative needs.

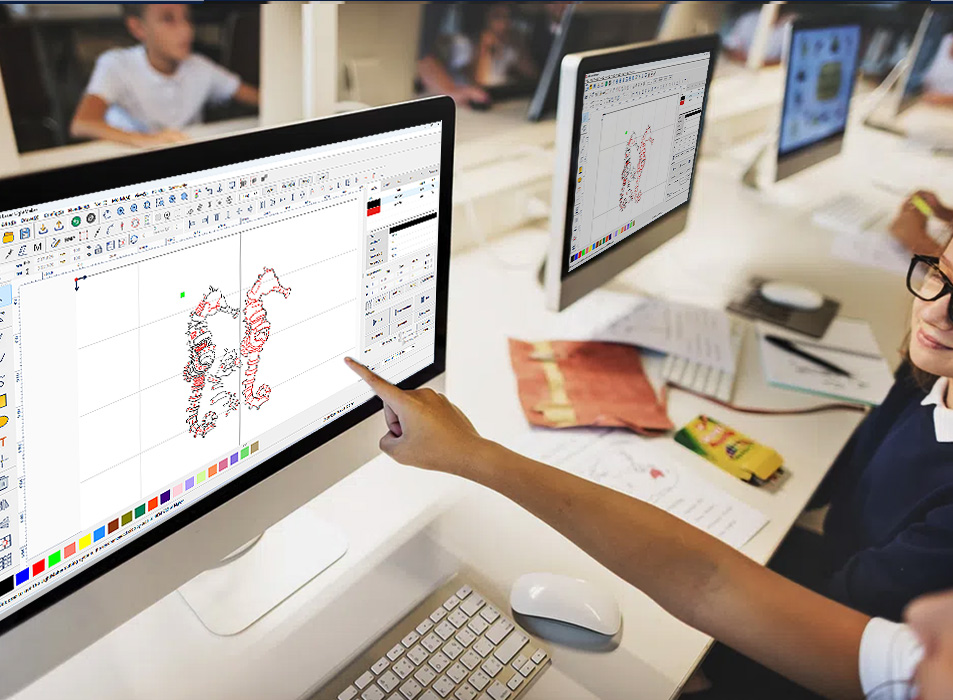

- Education industry: Provide efficient and accurate processing services for the production of teaching models, puzzles, and teaching aids.

Innovative design: meeting personalized and customized needs

The modern market has a growing demand for personalization and customization, and consumers prefer unique and creative customized products. Based on this trend,Good-Laser Light series provides innovative processing concepts, making personalized customization possible.

Through the perfect combination with computer-aided design systems and mobile phone apps, the Light series laser cutting and engraving machines can accurately perform cutting and engraving of any complex pattern, greatly expanding the boundaries of product design. This not only allows customers to customize products according to their personal needs, but also allows designers and artists to have more freedom in the creative process and express richer creativity.

Intelligent operation: simplify the process and improve the user experience

Good-Laser Light series laser cutting and engraving machines use an intelligent operating system, making it easier and more convenient for users to use. The equipment supports auto focus, auto positioning and online monitoring, and the operation interface is intuitive and easy to understand, so even users without professional background can easily get started.

The Light series is also equipped with an advanced fault diagnosis and maintenance system that can monitor equipment status in real time, issue early warnings, and reduce downtime. This allows manufacturers to resume normal production in the shortest possible time, avoiding unnecessary production losses.

Environmental protection and energy saving: innovative green manufacturing concepts

As global environmental awareness increases, many industries are looking for greener and more environmentally friendly production methods. Good-Laser's Light series is designed with full consideration of environmental protection and energy saving factors. Laser cutting and engraving technology itself does not produce exhaust gas and pollutants. Compared with traditional mechanical processing, laser processing is more environmentally friendly. In addition, the high energy efficiency design of the Light series equipment further reduces energy consumption, which meets the green development requirements of the modern manufacturing industry.

Good-Laser's Light series laser cutting and engraving machines are leading a new round of revolution in the field of laser processing with their precision, efficiency, intelligence and environmental protection. Whether it is large-scale production or personalized customization, the Light series can provide customers with tailor-made solutions to help companies improve production efficiency, reduce costs and increase market competitiveness.

Media Contact

Company Name: Good-Laser

Email: Send Email

Phone: +86 400-0606-086

Country: China

Website: https://www.good-lasermaker.com/